Tungsten Disulphide, also known as WS2, is a synthetic powder with the chemical formula WS2. The microstructure of WS2 Dry Film Lubricant crystals is a layered hollow sphere with hexagonal crystal clusters, and lamellar lattice structure, whose layers are bound by weak Van der Walls forces.

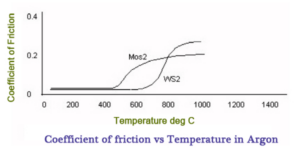

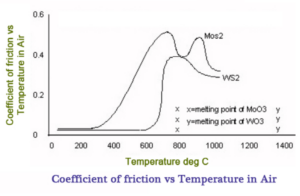

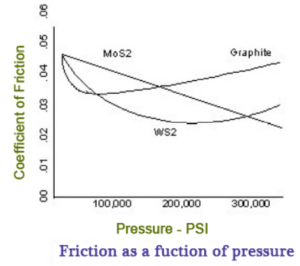

This weak binding force is easily shared between the layers, resulting in a very low coefficient of friction. Tungsten Disulfide is one of the most lubricious materials known to science.

There are some factors that make tungsten disulfide the coating of choice in many applications including spaceflight, aerospace, military, semiconductor, medical device, automotive and more.

Tungsten disulfide lubricant possesses certain significant advantages over many other classic inorganic solid lubricants; some of the attributes are listed below.

At Micro Surface Corporation in San Jose, CA, we offer premium tungsten disulfide coating services utilizing our proprietary WS2 per Process SL-39. Tungsten Disulfide Coating is applied using state-of-the-art equipment by our skilled technicians.

The tungsten disulfide coating process is performed at room temperature and requires no resins, binders or curing. Once the WS2 is properly applied, it will not crack or peel and becomes a part of a substrate. With the dimensional build-up of only 0.5 microns (0.00002”), tungsten disulfide will not affect normal machine tolerances, making it the lubricant of choice for many precision applications such as:

Besides the above-listed applications, the lubricant is applicable to many more applications where the reduction of friction and wear, elimination of galling and fretting, and service life extension are desirable.

| Appearance | Rhodium Silver Grey |

| Substrates | All ferrous or non-ferrous metal Man-made solids & plastics |

| Coefficient of Friction | Dynamic 0.030 Static 0.070 |

| Non Stick | Excellent |

| Food Contact | No |

| RC Scale | 1.0 to 1.5 |

| Flexibility | Excellent |

| Applied Thickness | 0.00002 Inch |

| Applications | Chucks, Collets and Tools Circuit Breakers and Switches Compressors and Rheostats Cryogenic Pumps Electrical Connectors Engine and Drive Train Parts High Vacuum Applications Machine tools, Pins, Taps Magnetic Heads Pilot Valves, Chain Saws Rubber Gaskets, “O” Ring Seals Seamer Rolls Slide Mechanisms |

| Cure Time | No cure time is required when applied at ambient temperature |

| Compliances | Military Spec DOD-L-85645 & AMS2530 |

| Relative Abrasion Resistance | Low |

| Relative Load Carrying | Same as substrate up to 100,000 PSI |

| 5% Salt Spray Rating | Impervious to Fuels,Solvents Minor Decay |

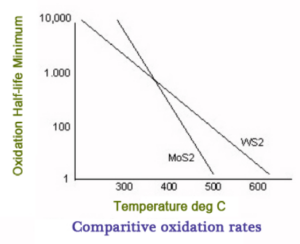

| Ambient Temperature Range | -273 to 650 ºC |

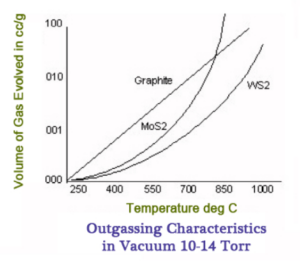

| Vacuum Temperature Range | -188 to 1316°C at 10-14 Torr |

| Relative Chemical Resistance | Good |

| Chemical Stability | Inert, non-toxic, corrosion resistant |

| Vacuum Environment | -188°C(-350°F) to 1316°C (2400°F) temperatures at 10-14 Torr |

| Lox Compatibility | Insensitive to detonation by or in the presence of oxygen |

| Corrosion Resistance | Minor deay of corrosion, Will not prevent corrosion of the substrate |

| Compliances | Military Spec DOD-L-85645 & AMS2530 |

| Composition | Modified Tungsten Disulfide (WS2) in Lamellar Form |

| Carrier | High velocity refrigerated air, no binders or adhesives |

| Adhesion | Mechanical (Molecular Interlock) |

| Magnetism | Non-magnetic |

| Hardness | Approximately 30 Rockwell C |

| Molecular Weight | 248.02 |

| Density | 7.4 gms/cc |